The Construction of Space Shuttle Launch Complex 39-B

A very personal and technical written and photographic history, by James MacLaren.

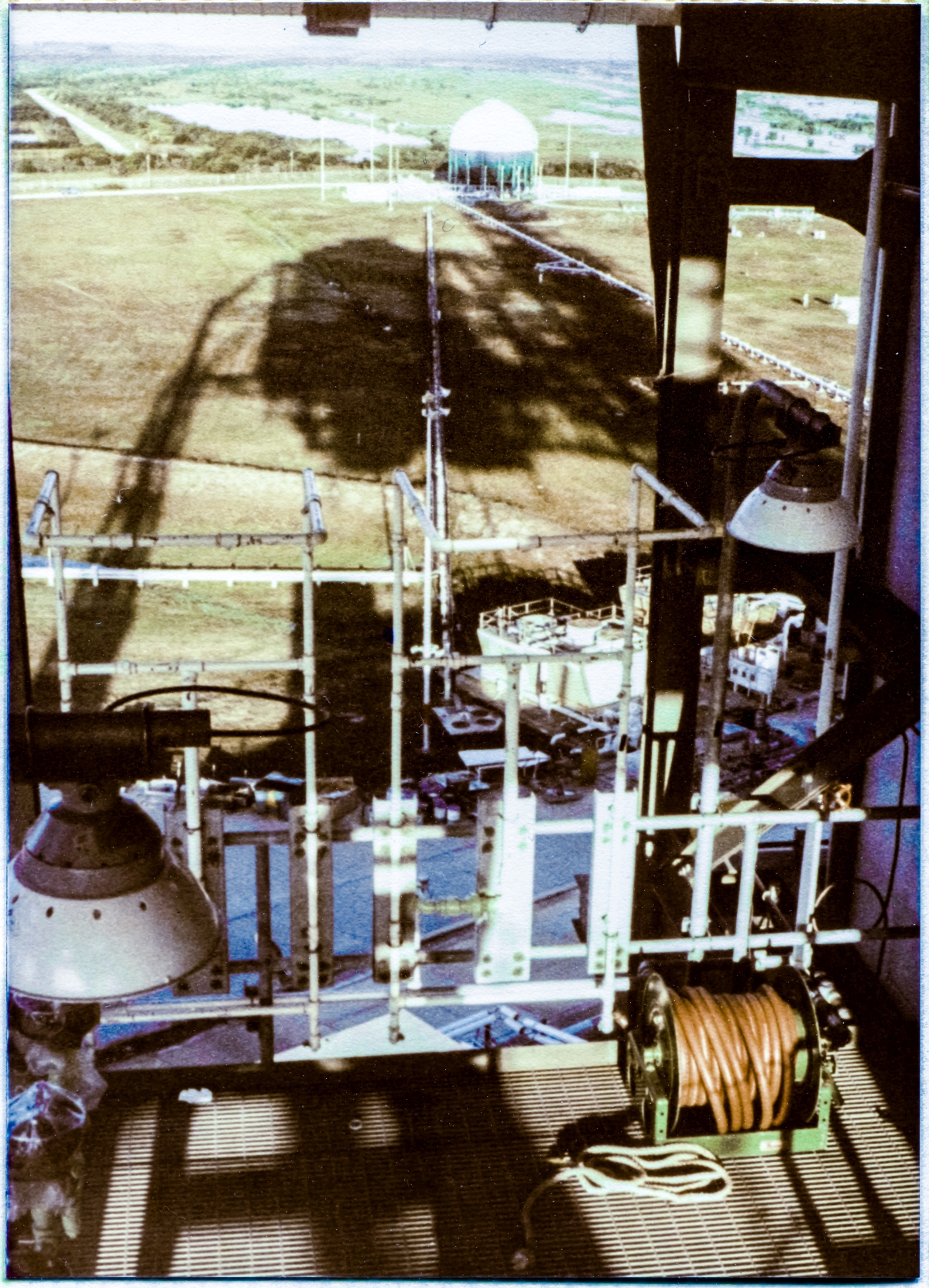

Page 33: RSS, Morning Light, Morning Shadow.

| Pad B Stories - Table of Contents |

We've been spending an awful lot of time over on the front of the RSS, and there's certainly plenty there to learn about, but let us walk around to the back of it for a moment, and consider our surroundings from here.

So.

Where are we? Exactly?

We are standing just below the intermediate landing of the middle set of risers on Stair Number 2, with our soles of our boots a few risers above the steel-bar grating on the lowest main floor-framing steel of the RSS at elevation 112'-0", which is visible along the bottom margin of the photograph ahead of us and below us. A quarter-mile distant, with a little bit of shadow from the top of the FSS on it, we can see the the great steel sphere of the Liquid Oxygen Dewar, which was originally built as part of the Apollo Moon-landing Program, and which continued to get used for the Space Shuttle Program that followed it.

The wintertime sun angle just happens to align near-perfectly with the direction that the Rotating Service Structure in its de-mate position is facing, resulting in a shadow on the open grass between ourselves and the LOX Dewar showing its outline in easily-recognizable detail, from the thickness of Stair Tower 3 straddling the thinner dark line of the Column Line 7 primary framing Steel on the far left, through the sunlit openness of additional primary framing steel between Lines 7 and 6, and past Line 6 the darkness of Stair Tower 4 with some light filtering through it near the top, and heading to the right from there, into the dark rectangular shape of the Payload Changeout Room between Lines 5 and 3, complete with recognizable silhouette of the upper edges of the RCS Room, the Hoist Equipment Room, and the Elevator Machinery Room stair-stepping leftwards down to the top of Stair Tower 4, with the somewhat more complex silhouettes of the framing steel of elevations 125'-0" and 112'-0" down at the bottom, beneath the PCR, defining the underside of the Great Arch of the RSS, complete with sunlit cutout for the Orbiter's tail in the middle, and then extending across the light-and-shadow area filled with primary framing, cable trays, catwalks, and crossover platforms on either side of Column Line 2, bracketed on the far right by the much taller shadow of the Fixed Service Structure.

It is as if someone decided to draw the RSS and FSS in dark pencil across an open field a quarter-mile across.

We are over on a far extremity of the RSS, on the Column Line 7 side of it, at the very bottom, with all of its main body above us and to the right of us.

Behind us, the stair riser will take us up to elevation 125'-0", and if we keep following it upwards, we'll take a bit of a turn and then find ourselves at the bottom of Stair Tower 4, which, if we keep walking, will take us all the way up to the RSS Roof at elevation 212'-1", and from there we might readily access any number of nearby places and things.

But not this morning.

To our right, just out of frame, a doorway provides an opening in the white insulated-metal paneling that surrounds things on the APS Servicing Platform which will give us access to the platforms and equipment in there, but again, not this morning.

To our left, a sheer drop to the Pad Deck, with an open vista above it, looking east and south, that takes in a wide swath of horizon from the Atlantic Ocean out of view behind us over our left shoulder, sweeping around towards the right, past the heavy iron of Column Line 7 with Stair Tower 3 intertwined within it and the distant VAB across the intervening wilderness far far beyond it, extending on farther to the right until it meets, blends, and becomes part of, the vista we now see directly in front of us, off to the northwest.

And in front of us?

Science Fiction.

That somehow became Science Fact.

And from where we stand, with our eyes of science fact, we can see that the Moon is not so very far away at all.

In the past.

In the present.

And in the future.

You'd walk around on the towers, and stuff like this would jump out at you from around hidden corners all the time and yet I never heard from a single other person about any of it.

It was as if they all had just decided to block it completely out, put their heads down as far as they could, and never let any of it enter their minds.

I never did, and never will, understand this mentality.

It just completely escapes me.

The beauty, the majesty, the symmetry, the power, the form, the otherworldly grace, and all the rest of it were arrayed everywhere around everyone, and yet none of them responded to any of it that I can recall.

I don't know.

I just do not know.

Ok, back to the picture.

What's going on here?

We'll start with things that are close to us, and just beyond the obvious lighting fixture on the lower left margin of the frame, there's a confusing array of small white pipes running vertically and horizontally at the far edge of the steel-bar grating just below us, with what appears to be a reel for a rolled-up garden hose over on the right-hand side.

What is this stuff, anyway?

And our first clue was given to us up above, when we were informed that we were just outside a doorway which leads to the APS Servicing Platform area of the RSS, which you may or may not remember that I gave the whimsical nickname of "Lower Hypergol World" and if you do, then the connection with hypergol is the clue.

We're looking directly at an emergency shower and eyewash station which would be used by affected personnel in the event of a hypergol spill.

It happens.

So they plan accordingly and these things are all over the tower, anywhere you have personnel access platforming in association with hypergolic fill and drain valving and plumbing on the tower or on flight hardware. They have already appeared in numerous places on previous photographs, and will continue to appear on subsequent photographs, and I'll leave it up to you to look for them, notice them and recognize them for what they are, wherever you might encounter them.

The good news is that hypergolic fuel (N2H4 and its cousins UDMH and Aerozine-50) and oxidizer (N2O4) are both readily-enough neutralized by copious amounts of water, so these shower/eyewash stations are set up to soak down and rinse off anybody or anything that winds up having the sort of bad day that involves getting hypergol on them, and hopefully that gets done immediately, before too much permanent damage to human flesh occurs.

And, while we're speaking of hypergol, look closely at the photograph immediately below the shower piping and just above the steel-bar grating of the platform below it, in that little gap there, and you'll notice a sort of white triangle shape in the distance. That "triangle" is the blast-proof concrete roof for the freight elevator which went from ground level to the Pad Deck over on this side of the Pad, and immediately to its right, you'll see the white external insulation on a pair of pipes that take a sharp bend, coming away from the elevator, looking like they're headed directly toward the hose reel there. Those pipes are what supplies hypergolic fuel and oxidizer for the entire RSS, which uses them in Upper Hypergol World, Lower Hypergol World, and inside of the Payload Changeout Room. And you can't be carpeting the whole world with emergency shower and eyewash stations, putting them everywhere, so you do the best you can with it, and you kind of keep it in the back of your mind, at all times, the stuff's there, everpresent, ever-patient.

On the steel-bar grating to the right of the emergency shower and eyewash station, another ubiquitous item can be seen in the form of that hose reel, which is for a firehose.

Here's the drawing for it, off of the 79K10338 package for the SSAT (FSS), but it's the same item, so you're ok using a different drawing package for it.

Firex water was all over the place on both towers, and for the most part was found as automatic fire-detection and suppression, in the form of overhead sprinklers, or as part of the pad water-deluge system which they turned on just a few seconds prior to engine ignition on launch day, but it also included these hose-reels, which were the sorts of things that you might at first kind of wonder about for a place like this. A place which routinely dealt with atomic-bomb equivalent quantities of extraordinarily volatile stuff, perhaps imagining to yourself some guy with what amounts to a garden hose futilely spraying water on a Space Shuttle, which is on fire, but there were plenty of other much-less dire possibilities, and if you had one of these firehoses and did not need it, well then, that's ok, and it's also vastly preferable to needing one, and not having it.

These hose reels were often, but not always, found in association with the shower/eyewash stations, but once in a while you'd find them on their own, in places. The water supply for the eyewash station was already there, so they kept things a little simpler by just coming off of that with another branch, and hooking it to the firehose, and saving themselves some time, and money, and trouble, by doing it that way. And yeah, if you needed to be able to unroll the firehose to run over someplace with it and douse something, or, god forbid, somebody, that could not be taken to the shower, well then, more's the better.

So.

Firehoses wound neatly on reels with nice strong blast covers for them to keep them intact, and ready for use, should need ever arise.

Off in the farther distance, just beyond the concrete margin of the Pad Slope, partially obscured by the emergency shower piping and structural framing beyond that, in white, with runs of handrail piping along their top perimeters, the two large cooling towers that served the ECS system can be seen. We'll delve a little deeper into the particulars of those cooling towers, and the ECS System which they served, a little be later on, ok? But not right now.

There's an interesting story with those cooling towers, and they're otherwise not particularly interesting items, and I may or may not be revisiting them later, so I may as well tell you that little story now, and it involves what we did to them after I returned to the Pad, working for Ivey Steel, after my Sheffield Steel days (when this picture was taken) were behind me.

Cooling towers are just about as mundane as it gets, and all large buildings and facilities in Florida (and a lot of other places too) will have a few of them somewhere, usually around back, where you can't see them, sometimes on top, shielded by a facade of sorts, and they do that because they are ugly, and if the architectural design people could figure out how to do it, they would eradicate them from the face of the earth, because, as I just said, they're ugly.

But they're vital, and without them conditioned air will not get conditioned, and in very short order indeed, living conditions inside the building would go from bad, to worse, to lethal, at which point the building in question becomes unusable because nobody can survive inside of it as heat and stale carbon-dioxide (and maybe other stuff too, depending) contaminated air steadily accumulates to life-terminating levels.

So. Fairly high penalty associated with not having these things around, ugly or no.

The basic setup for a cooling tower involves a contained area for the water used in the tower to fall into and be collected for reuse, and these things are dead-simple, and consist in a square concrete pad surrounded with low raised-concrete walls which form a basin to prevent the water from escaping, with a set of steel beams spanning the walls, side-to-side, that the cooling tower can sit on top of, allowing air to flow through it vertically.

Ok, so far, so good, so what's the big deal, anyway?

Well... it just so happens that the Cape Canaveral, Kennedy Space Center area is the most corrosive environment in North America.

I've talked about it before.

The air in Cape Canaveral is reactive.

And the steel sitting underneath those cooling towers did not fare well over time, and as part of Phase IV, working for Ivey Steel, they replaced the aging cooling towers, and we, as the structural-steel contractor, were the ones who replaced the steel beams underneath them, and NASA Engineering was not amused with how badly those original A36 mild-steel beams held up against the unbelievably-corrosive environment in which they were sitting, and decided to replace them with Stainless Steel.

And they don't roll structural shapes with stainless steel at the mill, and instead we wound up having to make them, welding them together into wide-flange shapes out of, if memory serves, lengths of half-inch stainless-steel plate.

And of course it was completely ridiculous, and part of me wonders if the engineers who called it out simply did so to see if they could get away with it or not (I saw such things done, in other places, with my own eyes), and nobody blew the whistle on any of it, and ok, "If that's what you want, then that's what we'll give you." And there must have been a dozen of these things across both of the cooling-tower basins, and they might have been.... oh, I don't know, maybe fifteen feet long, each (probably longer, but I'm trying to keep things on the conservative side for the purposes of this discussion), and they were simulacrums of 8-inch wide-flanges which were square in aspect, eight inches deep by eight inches wide, and... know what? I'm gonna go look in the Steel Book, right now, and see what a thing like that might weigh.

Ok.

Closest thing I could find to match that description (this is the first time I've ever done this with these pieces of steel) is a W8x58, and the dimensions are pretty close to what we had, and I'm going to just go ahead and round that weight per running foot down to a nice even fifty pounds, just because.

So... a couple of dozen of these things, for the pair of cooling tower basins, times fifteen feet long, times fifty pounds per foot...

...yields an even-heavier-than-I-thought-it-would-be total weight of 18,000 pounds of stainless steel!

Whoa!

God only knows what those things cost, just for the material alone. I wasn't part of any of that end of things on this one, and never got to see the numbers, but I'm sure they were very much eye-watering. For a couple of stupid cooling towers.

How engineering ever slipped it through, I'll never know.

But what I do know is that everybody, and I do mean everybody, who set eyes on those things was drooling at them, thinking about what it might all be worth, simply for scrap value.

But of course nobody ever managed to spirit them away from the jobsite, and disregarding any larcenous intent on the part of all who beheld them, we had our hands full with other problems with them, above and beyond their ridiculous material cost.

They were weldments after all, and the engineering goofuses who drew them up, and their higher-ups who approved the whole crack-brained scheme, didn't really grok the fullness of laying a hefty continuous fillet weld, full-length, both sides, where the fifteen foot long half-inch flat stainless-steel plate which became the web, met the fifteen foot long flat stainless-steel plate which became the flange.

And that's a significant pair of fillet welds (oh well, at least they didn't specify full-penetration welds) side-by-side, and it poured a significant amount of heat into the metal, and as steel will do, when simply welded (overwelded, really) in the absence of any additional pre or post weld heat-treatment, (none was spec'd out, none was so much as even hinted at, and none was offered as a charitable contribution by the fabricator) it drew. And it left the beams (laying on their sides) looking like this (---) with top and bottom flanges curved very noticeably down toward the web on both sides, curving down toward where all that run of fillet weld (and introduced heat flux) was.

And of course a shitstorm immediately erupted when the customer's representatives (the very same people who drew this stuff up in the first place) first laid eyes on how very non-flat the flanges of their ever-so-shiny new stainless-steel cooling tower supports were, and then of course they looked over at us and demanded we tell them what we were going to do about it, to "make it right."

And of course we answered right back, "We made it exactly as specified, and we are not going to be doing anything about it, and what, pray tell, might you want to do about it?

And it got real quiet for a little while there as they went and considered matters on their own.

And then they came back, and told us that it would be ok, and that they were going to very graciously not whack us with a credit against our contract (snowball's chance in hell with that one, guys), and just leave things be, as is.

Which we already knew was what they were going to do, because any kind of actual "fix" would have involved significant additional sums of both time and money, but more importantly, those beams, with those now-curved top and bottom flanges, were most very likely even stronger than originally specified, and the business of getting them to lay flat, and hold up the cooling tower nice and straight, was simplicity itself via the use of a few beveled washers, and that was that, then and there.

But they weren't done.

Despite the fact that they spec'd out, and received, stainless-steel beams, they still harbored grave misgivings about corrosion (the corrosion people, who were all new to me, and had somehow moved in and completely taken over on the NASA side of the house after I had left Sheffield, were not right in the head) and in addition to things being made from stainless steel (but only here, underneath the cooling towers, not a single structural member anywhere else on the whole pad), things also needed to be properly coated (they never called it "paint") against...

...corrosion?

Yep. Even though what was being coated was already stainless steel.

And so we were directed to apply a coating of something that memory is telling me went by the name of DuPont AR-7 Conformal Coating, which name I cannot find when I search for it, and which name I'm pretty sure I'm getting wrong somehow, which the painting contractor duly applied, followed immediately with a top coat of the standard pearl-gray stuff that went on all the other steel out there, but there's a part of me that thinks it was all a Great Ruse, just to ensure that the stainless steel was well-hidden enough to keep it from drawing unwanted attention... from thieves? From upper-level managers? From... I do not know.

And so it was done, and I filed it all away in my memory banks against the day that would surely come when those cooling towers got reworked, very likely involving the scrapping-out of the steel support beams underneath them, wondering if I'd ever get a chance to be the only guy who knew what that stuff really was, and grab it for a pittance, and drive away laughing up my sleeve.

But alas, it was not to be, and the Pad was converted for the SLS Program, and the RSS and FSS both went to the ground, but I really do not know, if that steel that we put under those cooling towers remains to this day...

...or not.

Maybe one of you guys oughtta head on out to Pad B, over around on the west side, and run your hands along whatever steel beams there are underneath the cooling towers, holding them up...

...and maybe let me know if they're kind of convexly-curved along their top surfaces.

Return to 16streets.comACRONYMS LOOK-UP PAGEContact Email Link |